We’re more than just our products – people are at the heart of everything we do.

The whole is greater than the sum of its parts.

– Merriam-Webster

We've refined the art of crafting products beyond compare.

This adventure is fun and, above all, a win-win for everyone: health-wise, financially and socially.

Dorothea, Switzerland

I'm inspired by the interconnection of body, mind and soul - only when all three are in harmony is a person happy and healthy, and that's exactly what we live and strive for at Lifeplus.

Petra, Germany

I’ve achieved what I never thought possible, absolute health and appreciation of myself as a person.

Sandra, Germany

What helps us feel good? No time pressure to achieve goals. Feeling free and positive. Being able to grow from challenges.

Jeany & Daniel, Belgium

I've changed my diet and my attitude towards my body. I'm also working hard on my mindset and trying to listen to myself more.

Ilka, Germany

Quality of Ingredients

Our commitment to quality – unique formulations using the finest ingredients

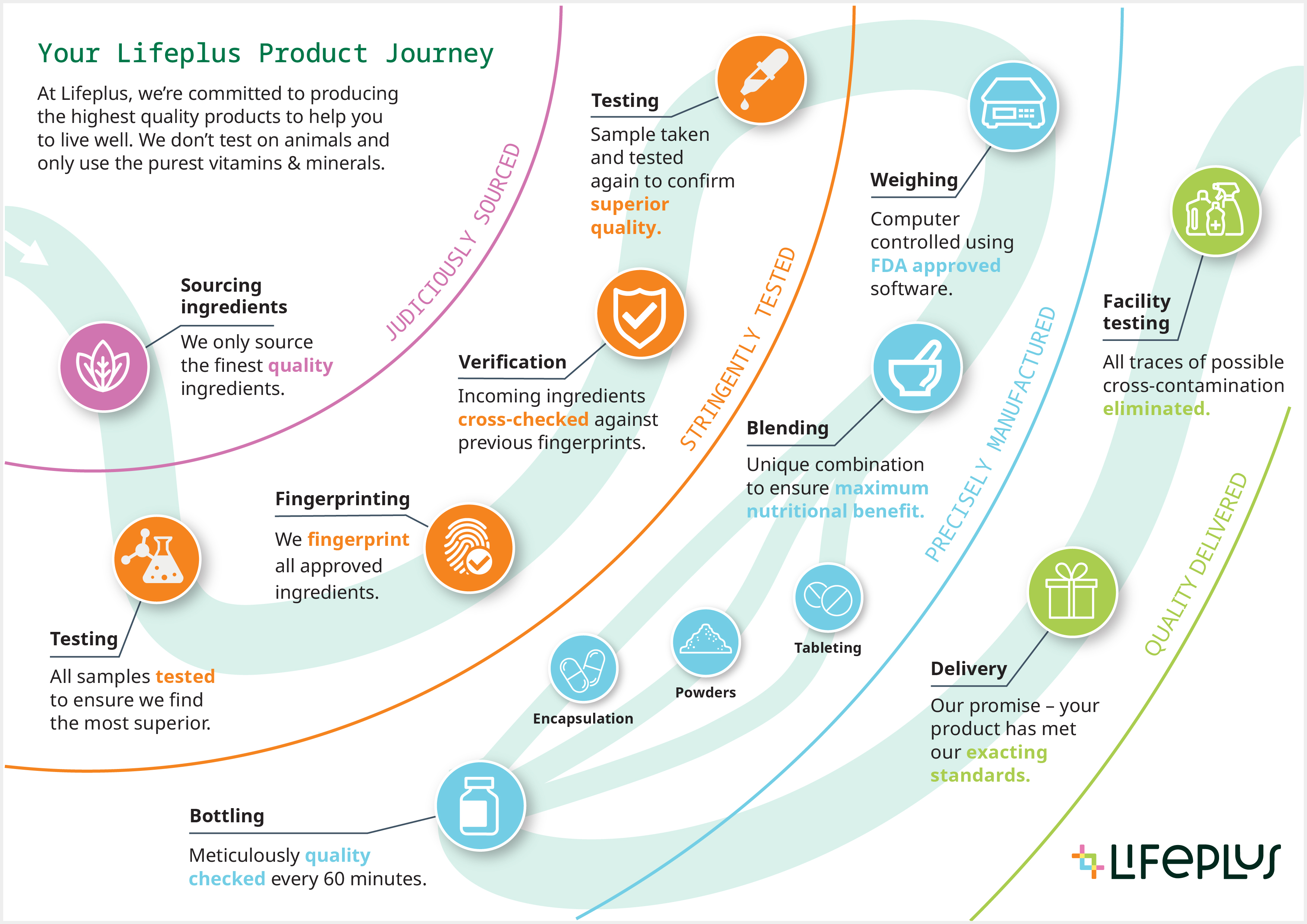

At Lifeplus, we manufacture nearly all of our own products. This way we can ensure quality is at the heart of everything we do. We monitor every detail from the purity of our source ingredients to the composition of the final product. Nothing leaves our premises unless we are absolutely certain it meets our exacting standards.

Unique formulations

Our in-house formulation team, led by our Scientific Director, Dr. Dwight McKee, stays abreast of the latest research by scouring the scientific literature, frequently attending health conferences, as well as surveying ingredient expos to find new potential sources of quality raw materials. This knowledge is then used to formulate synergistic combinations of ingredients for new and innovative holistic wellness products.

Ingredient Sourcing and Verification

Ingredient Sourcing and Verification

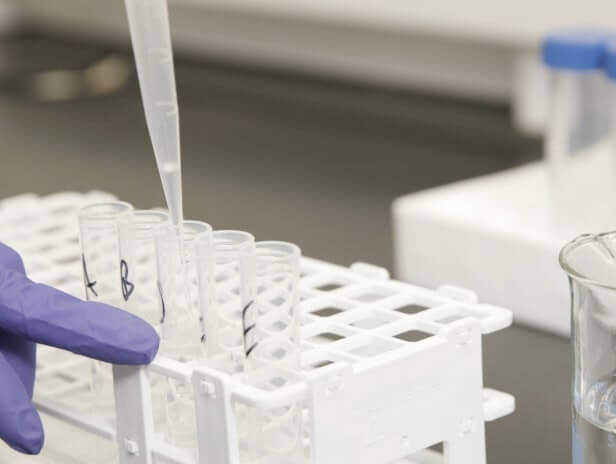

When a formula specifies an ingredient that we have not previously used, we will bring samples in from a variety of vendors. Our in-house Quality Assurance team will subject each sample to a battery of exacting laboratory tests. Potency, pesticides, herbicides, solvent residue, microbial growth, heavy metals and other parameters are all evaluated.

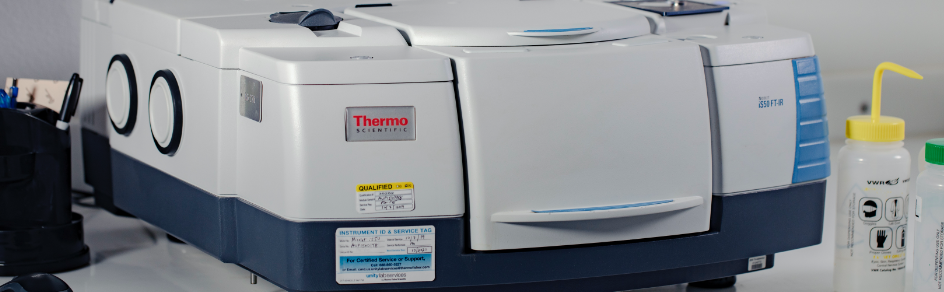

Lab equipment we use to verify our ingredients meet our specifications:

Water soluble vitamins

(e.g. B vitamins, vitamin C)

Amino acids

Phytonutrients: catechins & bioflavonoids

(e.g. EGCG in green tea, OPCs in grape seed extract, quercetin, rutin, hesperidin)

Other essential nutrients:

(e.g. CoQ10, choline)

Other elements

(e.g. mannose, ipriflavone, glucosamines, caffeine)

(e.g. polyphenols in green tea leaf extract, beta glucans)

(e.g. zinc, selenium, calcium, magnesium)

PCBs

Solvent residue

Vitamin E

(e.g. mercury, arsenic, lead, cadmium) down to parts per trillion

Fingerprinting

Fingerprinting

Once an ingredient has been identified as the preferred choice, it will be fingerprinted with our Fourier Transform Infrared Spectrometer (FTIR). This allows us to compare all future shipments of this specific ingredient to that fingerprint. If any future batch of an ingredient does not match the fingerprint, it is rejected and either returned to the vendor or discarded.

Future ingredient batches

Future ingredient batches

If the batch passes the fingerprinting test, it is quarantined while we run the full battery of laboratory tests described above. We need to satisfy ourselves that nothing has been altered and this batch of raw material is still as pure and clean as the initial sample received. This is the case even with regular highly commended suppliers. For example, we have used Real OPCs™ produced by the same supplier since 1994 and our Quality Assurance colleagues still test each and every delivery as if it were the first.

To see how we use quality ingredients to make quality products, click below.Quality of Manufacturing

Our commitment to quality – manufacturing to the highest standard

As with our ingredients and formulations quality drives the entire product creation journey, and is guaranteed by our dedicated Quality Assurance (QA) team.

The Manufacturing Journey

The Manufacturing Journey

The manufacturing journey begins and ends with our QA team. Ingredients are tested as soon as they enter the door and will continue to be monitored through every step of the process.

Ingredient weighing

Ingredient weighing

Our Quality Assurance team initiates production by preloading our automated weighing system with the appropriate formula for the desired product. The weighing of the ingredients is then computer controlled, virtually eliminating any possible human error. Even so, following weighing, the QA team examines the log from the scale to verify that all ingredients were weighed correctly.

“You might think it’s crazy for us to double check something that can’t be wrong? Maybe. But it is imperative that this critical step be absolutely correct.”

Blending

Blending

Weighed ingredients are then transferred into our custom-made stainless-steel totes. Quality Assurance verifies that the number of totes is consistent with the stipulated batch size. The totes are then moved to one of our various stainless-steel mirror-finished blenders. Over the years, with the growth of the company, we have added to our collection of blenders, with our largest now at 150 cubic feet. To put this in perspective, this large blender will hold just under 4,250 liters of liquid and is one of only a handful this size in the United States.

Once blended, QA samples the mixture and fingerprints it with our FTIR and compares it to the standard for that formula. If it passes, the mixture is again put into totes, which QA verifies are the proper number and weight. The totes are now ready to be moved to production stations.

Production Stations / Product Forms

The totes are either transferred directly to the powder-filling line for bottling, or if a tablet or capsule is to be made, they are transferred to the appropriate production station.

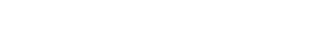

Tableting

Tableting

While we have multiple tablet presses in the facility, it is our two German high-speed, computer-controlled tablet presses capable of producing over 200,000 tablets per hour that see the most use. These presses are 2-5 times faster than the others and allow us to press over 3,300 bottles of Proanthenols® per hour.

Every 60 minutes during tableting, someone from QA will collect a sample to confirm that the press is still producing according to specification, notifying the operator if any adjustments are necessary. Samples taken during tablet production are assessed for size, durability, and dissolvability. If samples do not pass, processes are stopped, products not up to our specifications are discarded, any errors identified are corrected, and only then will production be allowed to proceed.

Encapsulating

Encapsulating

While not quite as fast as our tableting machines, our current encapsulation machine can produce up to 70,000 capsules per hour allowing us to produce over 1,100 bottles of Aloe Vera Caps per hour. As in tableting, samples of capsules are taken every 60 minutes.

Bottling

Bottling

We bottle our products using custom designed, automated, high-speed lines regardless of whether we are bottling our powders, tablets, capsules or soft gels. During bottling, QA pulls samples every 60 minutes.

While the exact order of the steps varies based on product form, each bottle of product is:

- Filled with designated amount of product

- Passed through an ultra-sensitive metal detector capable of finding metal fragments smaller than 1mm

- Capped and induction sealed, creating a tamper-evident seal

- Checked for appropriate weight

- Labeled with digitally printed labels that are created in-house on-demand for each batch of products

- Laser etched with tracking number and “Best Before” date

Further Testing

Further Testing

Our production may be finished but quality checks continue.

Cleanliness of Machinery

Once a batch of product is complete, the machinery is thoroughly cleaned, and then the Quality Assurance team will come through one more time to confirm that there is no trace of product OR any cleaning agents using our Total Organic Carbon (TOC) testing machine. Again, giving us the ability to be confident in our commitment to producing the cleanest products possible.

Product Testing & “Best Before” date

Samples from each and every batch of product are retained in order to confirm potency and purity for the entire lifespan through the “Best Before” date. We do not ‘skip-test’.

Quality program checks by the FDA

Our policies and procedures are audited and regulated by the US Food and Drug Administration (FDA) current Good Manufacturing Practices (cGMP) program; which means we are subject to regular unannounced audits to ensure ongoing compliance.

Our commitment to you; quality comes first

Quality is not a box-ticking exercise for us. It’s an obsession and one of which we are proud. We will never compromise our ethics or standards. That’s why you can rest assured you’re only ever getting the best.

Your Lifeplus Product Journey

Only One Planet Earth

At Lifeplus we recognize there is only one planet earth and it is everyone’s responsibility to take the best possible care of it.

For decades we have taken our responsibility seriously. We regularly consider not only the impact of our decisions on our current community, but also on future generations.

We know that the decisions we make can serve as examples for others around us. We know that the vendors we choose can help communities thrive. We know that what we did in the past has paved the way for today and what we do in the present can result in a better world tomorrow.

Our today

Learn more about what we are doing today.

Products

Taking great pride in our products

Our products:

- Are free of GMO* ingredients.

- Are not tested on animals.

- Are tested regularly, both the individual ingredients and the finished products, to verify they are exactly as they say.

- Are tested for, and free of, pesticides, herbicides, heavy metals and other contaminants.

- Are wrapped in packaging free of BpA.

- Do not contain micro-plastics.

Using environmentally friendly packaging when possible

Our packaging choice depends on the complete life cycle of the material used and its ability to deliver Lifeplus products to our consumers in the healthiest format possible with protection from:

We now use recyclable HDPE** plastic made from PCR*** materials for all products packaged by Lifeplus. This means all of our bottles, canisters, lids and tubs are made with a minimum of 97% PCR HDPE. Notable by their grey lids.

** High density polyethylene

*** Post-consumer recycled

People

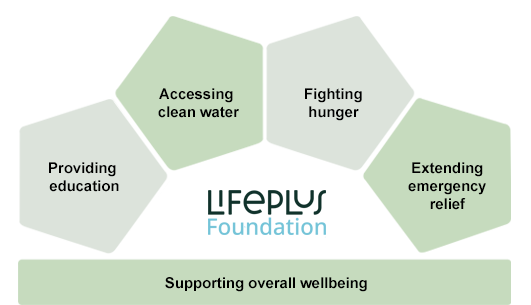

Community engagement with the Lifeplus Foundation

We are proud to share that, since 2001, our greater Lifeplus family has come together, by way of the Lifeplus Foundation, and collectively worked to fund community-based sustainability projects around the globe. Supported projects focus on improving access to clean water and sustainable food sources, increasing educational opportunities and extending emergency relief.

The need for food, water and education is everywhere and many in our Lifeplus community, and beyond, see this. They work together, organizing creative fundraising activities, so they can help people gain reliable access to these needs.

Fundraising and donations are changing lives. Lifeplus Foundation is careful to partner only with high-integrity charitable organizations that have low overhead costs, so that at least 90% of every donation goes directly to the cause.

We continue to look at how Lifeplus product donations can help communities in need too. And work with Lifeplus Foundation and partner organizations to deliver specific supplements that provide targeted relief.

Because these causes align with our mission of helping people around the world to live well, Lifeplus underwrites all operating expenses of the Lifeplus Foundation so that 100% of all donations go directly to the projects.

Lifeplus Foundation is a registered charitable organisation in the USA and Germany.

Learn more at www.lifeplusfoundation.org

Planet

Zero waste to landfill

Recycling efforts are prominent in all our offices. We recycle, reuse, or compost 99% of produced material waste at our UK office and have maintained “zero waste to landfill” certification since 2015.

zero waste to landfill 2015-2020

zero waste to landfill 2021

"Friend of the Sea" certified omega oils

Friend of the Sea is a globally supervised World Sustainability Organisation certification program. It has become the leading certification standard for products and services that are committed to positively contributing to the health of the oceans by promoting sustainable fishing practices.

Eco-Friendly employee elephant bike program

Supporting colleagues to use bikes whilst providing transportation for communities in Africa. This Cycle of Good – Elephant Bike Program provides a refurbished British postal bike for each one bought to communities in Malawi. To date we have purchased 10 bikes, including a trike and tandem, so colleagues from our UK offices can use these, in place of cars, during their working day. And we do so knowing someone in Malawi now has similar transportation for their day too.

Frequently Asked Questions

Does Lifeplus only source non-GMO ingredients?

Yes. Lifeplus requires all vendors to provide documentation certifying that ingredients purchased from them are free from GMOs. We feel strongly that the extra effort and expense are worth it.

Why aren’t all Lifeplus products from organic sources?

Organic ingredients can be limited in supply. We source these where we are able to do so but our principal concern is always with the purity of ingredient to ensure our products are derived from the cleanest sources we can find.

And we are excited to see more and more options. Not only in certified organic ingredients but also organic ingredients grown in sustainable, regenerative and community supportive ways. We remain committed to continuously evaluating the market to see where we can adjust such that we are purchasing from growers / suppliers who offer the cleanest and consistently highest quality ingredients possible.

Does Lifeplus source ingredients from sustainable farms?

Yes - where we can, we do.

Do any Lifeplus products contain micro-plastic?

No.

Why do you use HDPE [high density polyethylene] plastic as product packaging and how does that help the environment?

We use HDPE plastic, the best choice for product integrity, because it:

- Is inert, just like glass, but unlike glass:

- doesn’t break and therefore we don’t run the risk of our containers shattering.

- is lightweight, requiring less fuel and cost for transportation.

- Contains no BpA and / or phthalates. It’s stable to the point that nothing from the HDPE will "leach" into the contained product, even when heated.

- Is resistant to many chemicals, including acids, alcohols, esters and oils.

- Provides an impermeable barrier to block out light, air and moisture.

- Doesn’t support, or encourage, the growth of bacteria or other microorganisms.

- Is reusable. HDPE’s stability and inert nature makes its containers perfect for re-use.

- Is easy for our consumers to recycle from their home compared to other plastics.

- Is safe to burn [when done correctly by facilities set up to do so] reducing to just water and carbon dioxide.

And we now use 97% post-consumer waste recycled HDPE to save energy and reduce waste.

Our tomorrow

We understand our sustainability efforts are never complete …

As we continue to develop our relationships with established and new vendors, elevating our criteria to include a stronger emphasis on ingredients sourced through sustainable and regenerative agriculture, we remain committed to providing the best quality products possible.

And we have implemented an internal sustainability team who will continue to evaluate, implement and update our sustainability measures. From product ingredient selection to packaging solutions, from how we dispose of our waste to everything in between - we will continue to take sensible steps which improve our footprint on our one and only planet earth.